Sustainability in Manufacturing Operations Scheduling a State of the Art Review

Abstract

Recently, many manufacturing enterprises pay closer attention to energy efficiency due to increasing energy cost and environmental awareness. Energy-efficient scheduling of production systems is an effective style to improve energy efficiency and to reduce energy cost. During the past 10 years, a large amount of literature has been published well-nigh energy-efficient scheduling, in which more than 50% employed swarm intelligence and evolutionary algorithms to solve the complex scheduling bug. This newspaper aims to provide a comprehensive literature review of production scheduling for intelligent manufacturing systems with the free energy-related constraints and objectives. The main goals are to summarize, clarify, discuss, and synthesize the existing achievements, current research status, and ongoing studies, and to requite useful insight into future research, especially intelligent strategies for solving the energy-efficient scheduling problems. The scope of this review is focused on the journal publications of the Web of Scientific discipline database. The energy efficiency-related publications are classified and analyzed according to five criteria. Then, the inquiry trends of energy efficiency are discussed. Finally, some directions are pointed out for hereafter studies.

Introduction

Energy consumption is an of import issue in current lodge. In last 40 years, the free energy demand of the globe has doubled and will double again in side by side 10 years [ane]. In general, the industry is one of the primary consumers of free energy. In 2018, industry accounted for approximately 25% of free energy consumption by end utilise in the European Matrimony [ii]. The free energy consumption of industrial fields is about 26.three% of estimated U.Southward. energy consumption of 2018 [three]. As energy-intensive fields, manufacturing industries consumed nearly a tertiary of the global energy consumption of the earth [4, five]. In China, more than 56% of the full energy consumption is occupied in manufacturing sector attributed [6].

It is essential to reduce the manufacturing industry's energy consumption and demand. The manufacturing industries play a key role to satisfy continuously growing of diverse goods as living standards increasing. It is unrealistic to reduce the energy supply for manufacturing industries directly, since energy is a non-substitutable production factor. In other words, it is express to a certain extent to reduce free energy consumption and to discipline to the desired output simultaneously. Hence, how to better energy efficiency or to reduce energy demands for the same output becomes a critical approach to achieve the purpose of reducing energy consumption and developing sustainably. Information technology is a consensus in bookish and business that "free energy-efficiency gap" is a strong barrier which hinders energy-efficient manufacturing.

In manufacturing shops, the energy consumption is noticeable. In actual machining processes, motorcar tools stay in an idle state for the well-nigh of the time and consume nigh 80% energy with the idle state [seven]. Machine tools have huge potential space for energy saving [8]. In full general, scheduling is an effective approach to solve the issues almost automobile status and is an important decision-making process to decide which tasks to execute, when to execute them, and where to process them in which sequence. It is rarely considered every bit a suitable musical instrument to meliorate energy efficiency. In recent years, many researchers use scheduling approaches to improve energy efficiency in manufacturing industries and energy-efficient scheduling has been proved to exist an effective way of reducing the energy consumption with none or niggling capital investment [9, 10]. Energy efficiency or free energy consumption is considered equally constraints or scheduling objectives, like makespan, auto workload, and due-date objectives.

Production scheduling has been proven as an NP-difficult problem; hence, free energy-efficiency scheduling is no exception. Traditional optimization approaches cannot solve large-calibration scheduling problems with high efficiency, especially for some large-scale instances with real-time constraints. Therefore, swarm intelligence and evolutionary algorithms are employed for solving such problems as reported in many publications, since depression computational time and high efficiency are the most important criteria [4, 5]. For large-scale cases with existent-time constraints, swarm intelligence and evolutionary algorithms can obtain high-quality viable solutions in very brusque computational time. Swarm intelligence and evolutionary algorithms are becoming more and more popular for solving large-scale scheduling and optimization problems with time constraints, including free energy-efficiency scheduling in complex production.

The motivation of this review piece of work is the green manufacturing and energy-saving awareness in production scheduling area. The blueprint of intelligent scheduling strategies should consider free energy efficiency and reducing energy consumption which is an important scheduling objective in current production scheduling area. The purpose of this written report is to perform a literature review virtually production/store scheduling with considering energy-efficiency objectives. It can exist considered as a comprehensive reference for readers from both academia and industry. We will summarize existing achievements, clarify and discuss the current and ongoing research, and indicate some hereafter directions, especially the swarm intelligence and evolutionary algorithms for tackling such NP-hard problems. The balance of this paper is organized as follows. "Scope" department describes the scope of this review work. Afterwards, existing achievement is summarized and analyzed in "Classification" section. Next, detail discussion and analyzing upwardly to engagement and ongoing research in the field of production/store scheduling with free energy efficiency/consumption and constraints/objectives are given in "Research trends" department. Furthermore, some future research directions are also indicated in this section. Finally, this review paper is concluded in the last section.

Scope

An indispensable part of a literature review work is the review scope and purpose. The topic of this review is production/shop scheduling with energy efficiency, consumption, or toll as constraints or objectives, given in the post-obit: (one) the category of the shop flooring, (2) model of the scheduling bug, (iii) objectives (east.m., energy, completion time, machine workload, due date, and then forth), (4) research approaches (strategies) or algorithms, especially swarm intelligence and evolutionary algorithms, and (5) the aspects of energy consumption.

In some publications, energy efficiency or consumption is considered as constraints. Based on the topic and special review contents, we define the words "energy efficiency", "energy consumption", "energy cost", "product scheduling", "shop scheduling", "energy scheduling", "swarm intelligence", "evolutionary algorithm", and "meta-heuristics" as index keywords in the Web of Science database. As shown in Table 1, the energy keywords and the scheduling keywords work together to delimit the index results. In this department, we only indexed the journal articles and excluded books, theses, reports, and conference papers. The alphabetize results are shown in Table ii, including the names of journals and the number of relevant published papers in each journal is not less than 2. Hence, nosotros only focus to analyze, discuss, and synthesize the academic periodical publications, and do not consider publications with other publishing forms, since the most high-quality studies are published in the form of academic journals. In improver, we include some newest publications well-nigh the reviewed topic, which are not even so included in the Web of Science database at this moment. In total, to review the literature related to the "product/shop scheduling with energy efficiency or consumption equally constraints or objectives" topic, xc publications are analyzed, discussed, and synthesized till present. About 58% of articles are published in 13 journals (i.e., i journal published at least two papers). Amidst these journals, the Journal of Cleaner Production published the largest number of articles (xiii papers), while the International Periodical of Production Inquiry journal is placed in the second rank having 8 articles.

Classification, analysis, and synthesis of existing achievements

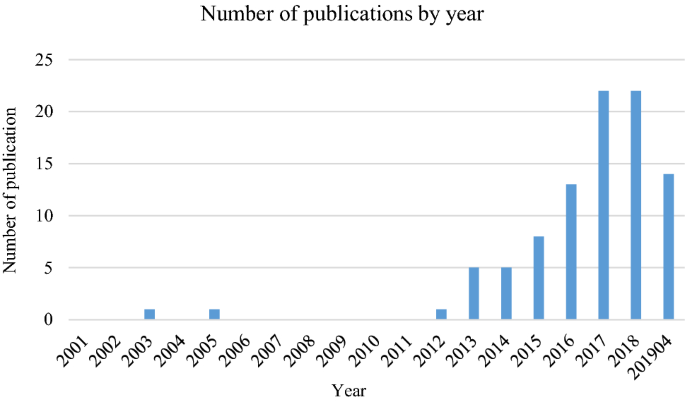

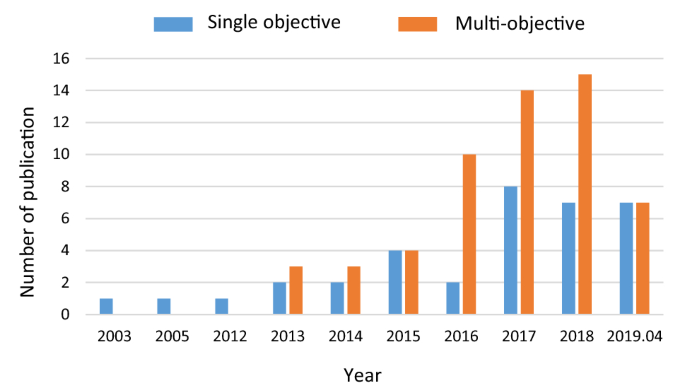

Every bit shown in Fig. 1, the number of publications addressing production scheduling with free energy-efficiency constraints or objectives increases rapidly since 2013. Particularly, in the first iv months of 2019, the number of published articles is larger than half of 2018 throughout the yr. These publications are classified by five criteria: shop floor category, problem model, scheduling objectives, solving approach (algorithms), and aspects of free energy consumption (see Table iii).

Twelvemonth-wise publication number addressing production scheduling with energy efficiency

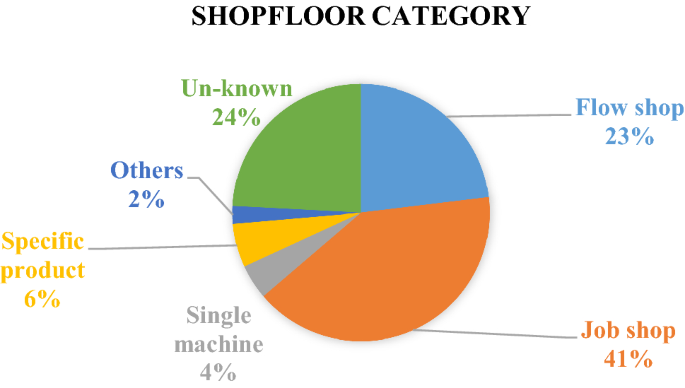

Shop flooring category

For production scheduling, store floor category is an important issue to distinguish problem model and solving strategies. Amongst the manufactures in Table 3, job shop (including flexible job shop)-related publication accounts 41% (see Fig. 2), the ratio of flow shop related articles is nigh 23%, and 4% publications are for single automobile scheduling. Some publications do not illustrate the special store floor category clearly and about half dozen% of articles addressed on a special product. Job store scheduling and menses store scheduling are considered as the most studied subjects, while the scheduling for a special product is rarely investigated. In fact, the energy-efficiency scheduling for a special product has more contributions and effects to the practise of scheduling theory and approaches.

Distribution of shop flooring category

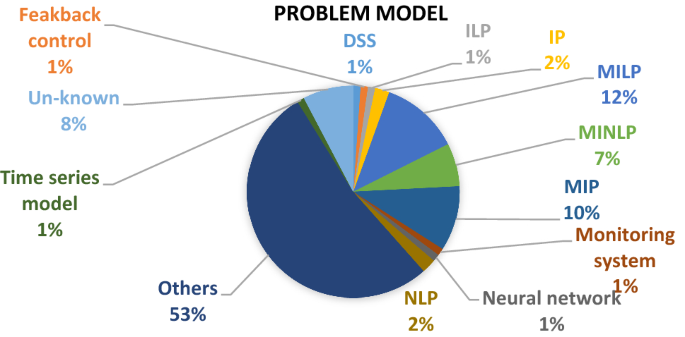

Problem models

With respect to the problem model, 34% of publications developed standard mathematical programme model, including integer programming (IP), integer linear programming (ILP), mixed integer linear programming (MILP), mixed integer non-linear programming (MINLP), mixed integer programming (MIP), and non-linear programming (see Fig. 3). Except standard mathematical models, some dissimilar models are used to describe energy-efficiency scheduling problems, including feedback control, neural network, decision support arrangement, monitoring organization, and fourth dimension-series model. In that location are quite a number of articles (53%) adult mathematical models; however, these models are not converted to standard mathematical program models or the authors did not state the model type clearly, it is categorized every bit "Others" class. We will discuss this situation in particular in the beginning part of adjacent section.

Model systems

Swarm intelligence and evolutionary algorithms

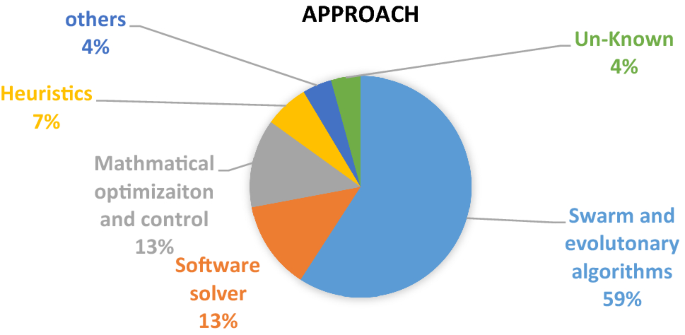

To solve energy-efficiency scheduling issues, many articles employed or improved swarm intelligence and evolutionary algorithms, e.m., genetic algorithm (GA), simulated annealing (SA), particle swarm optimization (PSO), shuffled frog-leaping algorithm (SFLA), greyness wolf optimizer (GWO), and and then forth. The detail analysis of these algorithms for free energy-efficiency scheduling volition exist shown in part one of "Research Trend" Department. To solve energy-efficiency scheduling problem, swarm intelligence and evolutionary algorithms do non demand standard mathematical models; indeed, they need mathematical formulations to compute objective functions. Amid all approaches, the ratio of swarm intelligence and evolutionary algorithms is 59%, which almost matches to the ratio of unstandard models (i.e., "Others" class), as shown in Fig. iii. Information technology ways that swarm intelligence and evolutionary algorithms are mainstream approaches for energy-efficiency scheduling, which has affected the problem modeling. The main procedures of swarm intelligence and evolutionary algorithms are shown as follows:

- one.

Initializing algorithm's parameters and the population.

- 2.

Evaluate initializing solutions in population and objectives values.

- three.

Generating new solutions based on the current solutions in population.

- iv.

Evaluate new solutions and replace the current ones.

- 5.

If the end criterion is not satisfied, go to Step (iii); else, get to Step (6).

- half dozen.

Stop and written report the best solution and corresponding objective values.

For dissimilar algorithms, the strategies to generate new solutions are different, and the end criterion is dissimilar. For different scheduling problems in intelligent product systems, there are dissimilar initializing rules and different local search operators.

To improve the convergence performance of swarm intelligence and evolutionary algorithms, some intelligent strategies are proposed in some reviewed articles. Here, nosotros introduce several representative ones. Wu et al. [79] proposed idle fourth dimension and machine turn on/off strategies for operation consignment and energy-saving purposes. Elapsed time for time turning off the idle machines is dependent on the length of idle time slots. May et al. [25] proposed an intelligent strategy to remove the overlapping solutions in the population initialization and new solutions generating phases. It can improve the multifariousness of population and avert echo solutions with the same function values. Zhang et al. [half dozen] developed an intelligent strategy to reduce energy consumption and improved energy efficiency in a production sequence fixed solution, past controlling the additional tardiness allowed for each job in the solution. These intelligent strategies amend the convergence performance of swarm intelligence and evolutionary algorithms, and their details tin be found in the corresponding manufactures.

Other approaches

By observing Fig. 4, the ratio of mathematical optimization and control approach is 13%, and the ratio of software solvers, e.one thousand., CPLEX, DICOPT, is likewise 13%. These two approaches need standardized mathematical models. The full ratio of these approaches (26%) is near to the ratio of standard mathematical programming models (34%) given in Fig. iii. In addition, 7% of articles employed heuristics to solve scheduling problems, which are too not strongly dependent on standard mathematical models of the scheduling problems. Furthermore, there are 4% manufactures use other approaches for solving free energy-related scheduling and 4% manufactures do non state the applied approaches clearly.

Approaches and algorithms attempted

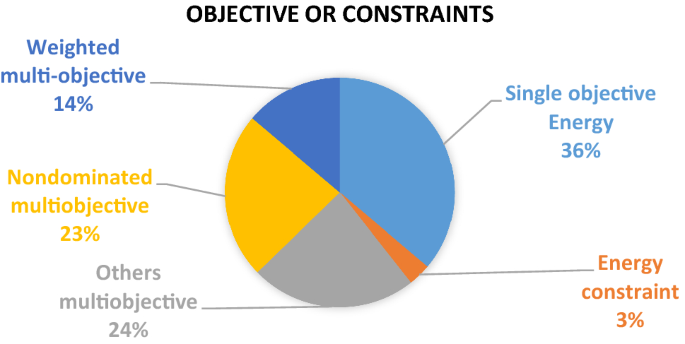

Objectives or constraints

The objectives of energy-efficiency scheduling are distinguished every bit single objective and multi-objective strategies. Single objective represents simply energy-related objective, including energy efficiency, free energy consumption, free energy price, and then forth. Multi-objective approaches means that energy objective and traditional scheduling objectives, east.g., completion fourth dimension-related objectives, machine workload-related objectives, due-date-related objectives and other objectives, are considered simultaneously. Based on the human relationship among different objectives, multiple objectives are solved in three forms, weighted summation, non-domination, and others (normalization or as constraints). It tin can be seen from Fig. 5 that the total ratio of multi-objective is nearly 61%, which is much larger than that of a unmarried objective (36%). It is mainstream to consider energy-related criteria equally a single objective or one of the multiple objectives fifty-fifty reporting by a few articles (3%) bold them as scheduling constraints. To improve energy efficiency and input–output ratio, the relationship amidst free energy-related objectives and traditional objectives must be more than investigated and analyzed.

Objectives systems

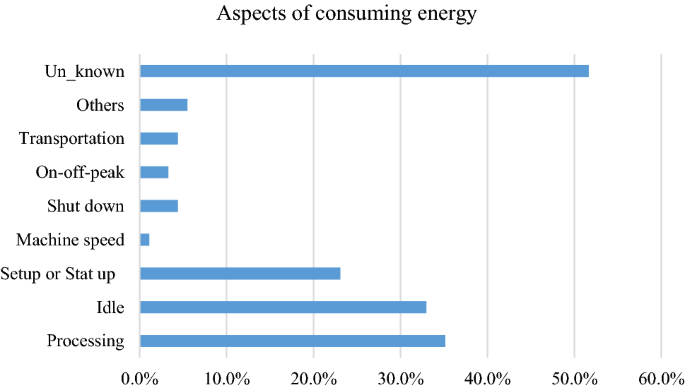

Aspects of energy consumption

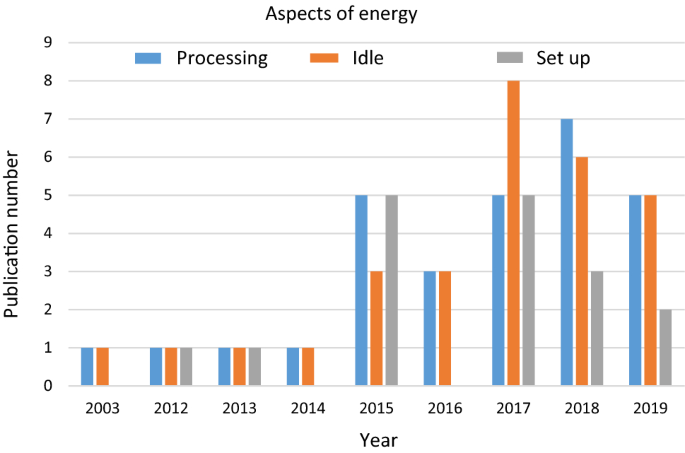

To reduce free energy consumption or increase free energy efficiency, it is a primal issue to clear the aspects of energy consumption or energy demand. Processing product, machine idle, machine setup and on/off, and product or components transportation are the aspects of free energy consumption considered the almost. The energy consumption in processing and machine idle is considered in more than thirty% reviewed articles, and the ratio of auto setup and on/off is larger than 20% (encounter Fig. 6). These three aspects of free energy consumption are the mainstream of energy-efficiency scheduling. More than 50% of publications have assumed free energy efficiency every bit scheduling objective; yet, the aspects of energy consumption or free energy need are not described conspicuously in these manufactures. Since one article may consider more than 1 aspects of energy consumption, the total ratio of all aspects in Fig. half-dozen is much larger than one.

Aspects of energy consumption

Research trends

The awareness of free energy efficiency, sustainability, and dark-green manufacturing, and production scheduling with energy objectives has becomes a hot topic in the past 5 years (see Fig. 1). From 2013, the number of published articles increases year by year. The number of published articles in 2017 and 2018 is more 20. Till April 2019, more than than ten production scheduling articles for energy-related objectives are published. Energy-related objectives become a new trend of product scheduling and will play vital and important role in production scheduling.

From single objective to multi-objective

Compared to traditional scheduling objectives, energy-related objectives are novel, however, important to economic indicators. The relationship between energy-related objectives and traditional objectives are analyzed and discussed in many publications. Many publications have considered energy-related objectives with traditional objectives simultaneously. From 2013 to Apr 2019, the number of articles for energy-related multi-objective scheduling is much larger than those for unmarried free energy-related objectives (see Fig. 7). It means that free energy-related scheduling objectives should exist considered together with traditional objectives for obtaining ameliorate determination-making by different functioning indicators.

Yr-wise comparisons of unmarried objective and multi-objective publications

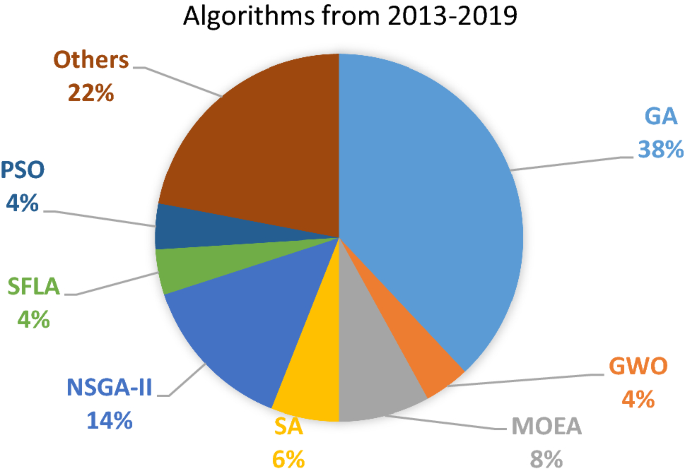

Swarm intelligence and evolutionary algorithms

With respect to approaches for solving energy-related scheduling objectives, swarm intelligence and evolutionary algorithms account 59% among various different approaches (see Fig. four), and all these articles are published later 2013. The GA as ane of classical evolutionary algorithm and a multi-objective GA (NSGA-2) are the most employed optimizer for solving the production scheduling issues (see Fig. viii).

Swarm and evolutionary algorithms for solving free energy-related scheduling

The total ratio of GA and NSGA-II is about 52% among all swarm intelligence and evolutionary algorithms. Abreast the NSGA-II, multi-objective evolutionary algorithm (MOEA) is besides used in well-nigh viii% manufactures. The ratios of SA, PSO, shuffled frog-leaping algorithm (SFLA), and Grayness wolf optimizer (GWO) are equal to or larger than iv%. The algorithms with ratios less than 4% are recorded as "Others" class and the total ratio of them is 22%, which means that at least six swarm intelligence and evolutionary algorithms are included in the "Others" class. Totally, more than 13 algorithms are employed or improved for solving product scheduling problems with energy-related objectives in the past 5 years. In fact, swarm intelligence and evolutionary algorithms are effective and widely used for solving energy-efficiency scheduling problem.

Extending of energy consumption aspects

In the reviewed literature, the energy consumption in a product process mainly includes two parts, processing energy and not-processing energy. The non-processing energy mainly includes idle energy and setup time. From 2015, more publications focus on these iii free energy consumption aspects (i.e., processing free energy, idle energy, and setup energy) and the full number of articles for processing energy (i.e., 25 articles) and idle free energy (i.e., 25 articles) are larger than that for setup energy (i.e., fifteen articles) (seen in Fig. ix). Since energy is a non-substitutable production factor, setup energy is a necessary pace for manufacturing. It is a realistic style to better machines' efficiency, reduce processing fourth dimension, and reduce the machine idle fourth dimension. In addition, the transportation energy amongst production is considered in some publications, it is likewise a potential style to reduce energy consumption (see Fig. 6).

Year-wise aspects of energy consumption

In summary, energy-related objectives are aware of production scheduling from 2012, particularly in the past 5 years. In view of the high complexity of production scheduling, many swarm intelligence and evolutionary algorithms are employed and improved to solve this problem. Free energy-related objectives are optimized with traditional scheduling objectives, simultaneously. The master aspects of energy consumption, e.one thousand., processing energy, idle, and setup energy, in a production procedure are modeled and evaluated. Some researchers have started to consider other energy consumption in a production process, for instance, energy for component transportation [80, 88].

Future directions

Based on the previous analysis of inquiry trends of production scheduling with energy-related objectives, nosotros consider and bespeak some future research directions for this topic.

Modeling of energy efficiency-related constraints and objectives

All aspects of energy consumption in production should be classified based on necessity and possibility of reducing the cost. The aspects of energy consumption with reduction possibility should be considered and modeled as scheduling constraints or objectives in product scheduling. The more aspects of energy consumption with reduction possibility are modeled, the higher possibility to reduce energy consumption and to amend energy efficiency.

Assay of the human relationship between energy-related objectives and the traditional objectives

Production scheduling is a multi-objective problem. Energy-related objectives are emerging targets compared to traditional objectives, east.1000., completion time, car workload, due date, and so on, The relationship between energy-related objectives and the traditional objectives must exist researched and analyzed. Does energy-related objective conflict to a certain extent with traditional objectives? Information technology is a precondition to solve free energy-efficiency scheduling and does not affect the optimization of other goals.

Developing swarm intelligence and evolutionary algorithms

Based on the synthesis and assay in above 2 sections, swarm intelligence and evolutionary algorithms are efficient and effective to solve energy-efficiency scheduling issues, particularly for the large-scale problems. How to design and develop more high-quality algorithms, specially not-dominated multi-objective algorithms, for solving energy-efficiency scheduling problem which is an important direction. Some local search operators based on the feature of energy-efficiency scheduling tin conduce to improve the convergence speed of swarm intelligence and evolutionary algorithms. Algorithmic accurateness and time efficiency are the cardinal functioning indicators.

Energy efficiency-based multi-objective scheduling strategy

Free energy-efficiency scheduling is an important objective in intelligent production system. At that place are some other objectives, e.g., completion fourth dimension-related objectives, automobile workload-related objectives, and the due appointment-related objectives and so forth. How to design energy efficiency-based multi-objective scheduling strategy is a novel and interesting direction. Especially, the not-boss strategy for multi-objective scheduling is the central outcome to improve algorithms' performance.

Develop energy-efficiency intelligent scheduling framework

Energy-efficiency scheduling is a novel topic in production scheduling. It would exist a bang-up contribution to this topic if a full general framework, particularly an intelligent scheduling framework, can be established, which can guide the inquiry and development of this topic. For free energy-efficiency scheduling, it would be a expert way to be integrated into the overall framework of production scheduling and to be embedded into an intelligent scheduling framework with intelligent scheduling strategizes. Furthermore, the existing modeling strategies, solving approaches and algorithms (including swarm intelligence and evolutionary algorithms), and benchmark instances for general production scheduling can be straight applied to free energy-efficiency scheduling or be used subsequently appropriate adjustments.

Practice in some special fields and even special products

For production scheduling, manufacturing enterprises are more focused on the practicality of models and algorithms, especially for a special product. Till now, few published manufactures addressed on this affair because of since the complexity and multi-constraints in real-life situations. It is an important and applied piece of work to model energy-efficiency scheduling for a special production and develop a loftier-quality meta-heuristic to solve information technology. This research direction can effectively promote Industry-University-Inquiry Collaborations.

Conclusions

The growing sensation of energy efficiency and sustainable evolution has led to persistent attention to energy efficiency in production scheduling. The growing number of published manufactures, especially in the past 5 years, makes energy-efficiency scheduling a hot research topic. In the review procedure of this review work, there are several newest publications related to the telescopic of this review paper [95,96,97,98,99] which shows the importance and high relevancy of the studied subject. Intelligent strategies are used past many researchers in scientific customs. This study presented the review of v indicators, including store flooring, models, approaches and algorithms, objectives, and aspects of free energy consumption in the literature for solving energy-efficiency scheduling problems. Intelligent strategies, including swarm intelligence, evolutionary algorithms, and improvement strategies, are synthesized, discussed, and analyzed in detail. Furthermore, the current research trends, peculiarly the intelligent strategies, are analyzed and summarized. For the continued written report of this topic, v instructive directions, including modeling, objectives, intelligent strategies, intelligent scheduling framework, and do, are given which provide an insight for future studies.

References

-

May Thou, Stahl B, Taisch M, Prabhu V (2015) Multi-objective genetic algorithm for energy-efficient chore shop scheduling. Int J Prod Res 53(23):7071–7089

-

Key figures on Europe, statistics illustrated, 2018 edition. https://ec.europa.eu/eurostat/documents/3217494/9309359/KS-EI-xviii-001-EN-Due north.pdf/0b8d8b94-541d-4d0c-b6a4-31a1f9939a75

-

Stark AM (2019) U.Southward. energy use rises to highest level ever. Lawrence Livermore National Laboratory (LLNL) news release

-

Meng LL, Zhang CY, Shao XY et al (2019) MILP models for energy-enlightened flexible job shop scheduling problem. J Make clean Prod 210:710–723

-

Meng LL, Zhang CY, Shao XY et al (2019) Mathematical modelling and optimisation of energy-witting hybrid flow shop scheduling problem with unrelated parallel machines. Int J Prod Res 57(4):1119–1145

-

Zhang R, Chiong R (2016) Solving the energy-efficient chore shop scheduling problem: a multi-objective genetic algorithm with enhanced local search for minimizing the total weighted tardiness and full energy consumption. J Clean Prod 112:3361–3375

-

Mouzon G, Yildirim MB, Twomey J (2007) Operational methods for minimization of free energy consumption of manufacturing equipment. Int J Prod Res 45(xviii–19):4247–4271

-

Li Fifty, Sun ZY, Yao XF, Wang DH (2016) Optimal product scheduling for energy efficiency improvement in biofuel feedstock preprocessing considering piece of work-in-process particle separation. Free energy 96:474–481

-

Lora AT, Riquelme JC, Ramos JLM, Santos JMR, Exposito AG (2003) Application of evolutionary computation techniques to the optimal short-term scheduling of the electrical energy production. Curr Top Artif Intell 3040:656–665

-

He Y, Liu F, Cao HJ, Li CB (2005) A bi-objective model for job-shop scheduling trouble to minimize both energy consumption and makespan. J Cent S Univ Technol 12:167–171

-

Bruzzone AAG, Anghinolfi D, Paolucci K, Tonelli F (2012) Free energy-enlightened scheduling for improving manufacturing process sustainability: a mathematical model for flexible catamenia shops. CIRP Ann-Manuf Technol 61(one):459–462

-

Cao VL, Pang CK, Gan OP et al (2013) Nomenclature of energy consumption patterns for free energy audit and machine scheduling in industrial manufacturing systems. Trans I Measure Command 35(five):583–592

-

Chen GR, Zhang L, Arinez J, Biller Southward (2013) Energy-efficient production systems through schedule-based operations. IEEE Trans Autom Sci Eng 10(one):27–37

-

Dai M, Tang DB, Giret A et al (2013) Energy-enlightened resources service scheduling based on utility evaluation in cloud manufacturing system. Proc Inst Mech Eng B J Eng Manuf 227(12):1901–1915

-

Moon JY, Shin K, Park J (2013) Optimization of production scheduling with time-dependent and car-dependent electricity toll for industrial energy efficiency. Int J Adv Manuf Technol 68(one–iv):523–535

-

Jiang ZQ, Zuo L, Mc Due east (2014) Study on multi-objective flexible chore-shop scheduling problem considering free energy consumption. J Ind Eng Manage 7(3):589–604

-

Moon JY, Park J (2014) Smart product scheduling with time-dependent and machine-dependent electricity cost by because distributed energy resources and energy storage. Int J Prod Res 52(13):3922–3939

-

Pach C, Berger T, Sallez Y et al (2014) Reactive and free energy-aware scheduling of flexible manufacturing systems using potential fields. Comput Ind 65(3):434–448

-

Shrouf F, Ordieres-Mere J, Garcia-Sanchez A et al (2014) Optimizing the production scheduling of a unmarried auto to minimize total free energy consumption costs. J Clean Prod 67:197–207

-

Zhang H, Zhao F, Fang K et al (2014) Energy-conscious flow shop scheduling under time-of-utilize electricity tariffs. CIRP Ann-Manuf Technol 63(1):37–40

-

Dai M, Tang DB, Xu YC et al (2015) Energy-aware integrated procedure planning and scheduling for chore shops. Proc Inst Mech Eng B J Eng Manuf 229:13–26

-

Duerden CJ, Shark LK, Hall Thousand et al (2015) Minimisation of energy consumption variance for multi-procedure manufacturing lines through genetic algorithm manipulation of production schedule. Eng Lett 23(1):forty–48

-

Garcia-Santiago CA, Del Ser J, Upton C (2015) A random-key encoded harmony search approach for energy-efficient production scheduling with shared sources. Eng Optimiz 47(11):1481–1496

-

Lee S, Prabhu VV (2015) Free energy-aware feedback control for production scheduling and capacity control. Int J Prod Res 53(23):7158–7170

-

May G, Stahl B, Taisch Yard et al (2015) Multi-objective genetic algorithm for energy-efficient task shop scheduling. Int J Prod Res 53(23):7071–7089

-

Tang DB, Dai One thousand (2015) Free energy-efficient approach to minimizing the energy consumption in an extended job-shop scheduling problem. Chin J Mech Eng 28(5):1048–1055

-

Tong CD, Palazoglu A, Ei-Farra NH et al (2015) Energy demand management for process systems through production scheduling and control. AIChE J 61(xi):3756–3769

-

Zhang H, Zhao F, Sutherland JW (2015) Energy-efficient scheduling of multiple manufacturing factories under existent-fourth dimension electricity pricing. CIRP Ann-Manuf Technol 64(one):41–44

-

Joan Escamilla, Salido MA, Giret A (2016) A metaheuristic technique for energy-efficiency in job-shop scheduling. Knowl Eng Rev 31(5):475–485

-

Oddi A, Rasconi R (2016) Leveraging constraint-based approaches for multi-objective flexible flow-store scheduling with free energy costs. Intell Artif 10(2):147–160

-

Salido MA, Escamilla J, Barber F (2016) Energy efficiency, robustness, and makespan optimality in job-shop scheduling problems. AI Edam 30(three):300–312

-

Salido MA, Escamilla J, Giret A, Barber F (2016) A genetic algorithm for free energy-efficiency in job-shop scheduling. Int J Adv Manuf Technol 85(5–8):1303–1314

-

Su LJ, Tang LX, Grossmann IE (2016) Scheduling of corking production process with feedstocks and energy constraints. Comput Chem Eng 94:92–103

-

Tang DB, Dai M, Salido MA, Giret A (2016) Energy-efficient dynamic scheduling for a flexible flow shop using an improved particle swarm optimization. Comput Ind 81:82–95

-

Tonelli F, Bruzzone AAG, Paolucci M (2016) Assessment of mathematical programming and amanuensis-based modelling for off-line scheduling: application to energy enlightened manufacturing. CIRP Ann-Manuf Technol 65(ane):405–408

-

Tong YF, Li JW, Li S, Li DB (2016) Enquiry on free energy-saving production scheduling based on a clustering algorithm for a forging enterprise. Sustainability eight(2):136

-

Yan JH, Li 50, Zhao F (2016) A multi-level optimization approach for energy-efficient flexible menstruum store scheduling. J Make clean Prod 137:1543–1552

-

Yang Ten, Zeng ZX, Wang RD, Lord's day XS (2016) Bi-objective flexible job-store scheduling problem considering free energy consumption under stochastic processing times. PLoS I 11(12):i–thirteen

-

Giglio D, Paolucci Thousand, Roshani A (2017) Integrated lot sizing and free energy-efficient task shop scheduling problem in manufacturing/remanufacturing systems. J Make clean Prod 148:624–641

-

Gong 10, Van der Wee M, De Pessemier T (2017) Integrating labor awareness to energy-efficient production scheduling under real-time electricity pricing: an empirical study. J Clean Prod 168:239–253

-

Kim SJ, Meng C, Son YJ (2017) Simulation-based motorcar store operations scheduling system for energy cost reduction. Simul Model Pract Theory 77:68–83

-

Lee S, Exercise Chung B, Jeon HW et al (2017) A dynamic control approach for energy-efficient production scheduling on a single automobile under time-varying electricity pricing. J Clean Prod 165:552–563

-

Lei DM, Zheng YL, Guo XP (2017) A shuffled frog-leaping algorithm for flexible job store scheduling with the consideration of energy consumption. Int J Prod Res 55(11):3126–3140

-

Liu GS, Zhou Y, Yang HD (2017) Minimizing energy consumption and tardiness penalty for fuzzy flow shop scheduling with land-dependent setup fourth dimension. J Make clean Prod 147:470–484

-

Lu C, Gao 50, Li XY et al (2017) Energy-efficient permutation flow shop scheduling trouble using a hybrid multi-objective backtracking search algorithm. J Make clean Prod 144:228–238

-

Misra Due south, Kapadi K, Gudi RD (2017) Energy-efficient product scheduling of a cryogenic air separation establish. Ind Eng Chem Res 56(15):4399–4414

-

Modos I, Sucha P, Hanzalek Z (2017) Algorithms for robust production scheduling with energy consumption limits. Comput Ind Eng 112:391–408

-

Mokhtari H, Hasani A (2017) An free energy-efficient multi-objective optimization for flexibl chore-shop scheduling problem. Comput Chem Eng 104:339–352

-

Otis PT, Hampson D (2017) Improve production scheduling to increment energy efficiency. Chem Eng Prog 113(3):45–51

-

Plitsos S, Repoussis PP, Mourtos I (2017) Energy-enlightened conclusion support for product scheduling. Decis Back up Syst 93:88–97

-

Rahimi AR, Ziaee M (2017) Modeling and solving the permutation flow shop scheduling trouble with limited buffer and the objectives of the minimization of total energy consumption and makespan. AD ALTA J Inter Res 7(ane):137–148

-

Raileanu S, Anton F, Iatan A (2017) Resources scheduling based on energy consumption for sustainable manufacturing. J Intel Manuf 28(7):1519–1530

-

Ramos AG, Leal J (2017) ILP model for energy-efficient production scheduling of bit ice units in nutrient retail stores. J Clean Prod 156:953–961

-

Sundstrom N, Wigstrom O, Lennartson B (2017) Conflict between energy, stability, and robustness in product schedules. IEEE Trans Autom Sci Eng 14(ii):659–668

-

Wang XN, El-Farra NH, Palazoglu A (2017) Optimal scheduling of demand responsive industrial product with hybrid renewable energy systems. Renew Energ 100:53–64

-

Xu JJ, Wang L (2017) A feedback control method for addressing the production scheduling trouble by considering energy. Sustainability ix(seven):1185

-

Yin LJ, Li XY, Gao Fifty et al (2017) Energy-efficient chore store scheduling problem with variable spindle speed using a novel multi-objective algorithm. Adv Mech Eng 9(4):1687814017695960

-

Zhai YX, Biel Yard, Zhao F et al (2017) Dynamic scheduling of a flow store with on-site wind generation for free energy cost reduction under real time electricity pricing. CIRP Ann-Manuf Technol 66(i):41–44

-

Zhang H, Zhao F, Sutherland JW (2017) Scheduling of a single flow store for minimal energy toll under real-time electricity pricing. J Manuf Sci E-T ASME 139(ane):14502

-

Zhang H, Dai ZW, Zhan Westward (2017) A new energy-aware flexible job store scheduling method using modified biogeography-based optimization. Math Probl Eng 2017:7249876

-

Aghelinejad MM, Ouazene Y, Yalaou A (2017) Product scheduling optimisation with machine state and time-dependent energy costs. Int J Proc Res 56(16):5558–5575

-

Escamilla J, Salido MA (2018) A dual scheduling model for optimizing robustness and energy consumption in manufacturing systems. P I Mech Eng B-J Eng 232(ane):5–16

-

Feng YX, Wang QR, Y Y (2018) Energy-efficient job-shop dynamic scheduling system based on the cyber-concrete free energy-monitoring system. IEEE Access half-dozen:52238–52247

-

Jiang Th, Deng GL (2018) Optimizing the low-carbon flexible job shop scheduling problem considering energy consumption. IEEE Access vi:46346–46355

-

Jiang TH, Zhang C, Zhu HQ et al (2018) Free energy-efficient scheduling for a job shop using gray wolf optimization algorithm with double-searching fashion. Math Probl Eng 2018:8574892

-

Jiang Th, Zhang C, Zhu HQ et al (2018) Energy-efficient scheduling for a task shop using an improved whale optimization algorithm. Mathematics six(11):220

-

Khalaf AF, Wang Y (2018) Energy-cost-aware menstruum shop scheduling considering intermittent renewables, free energy storage, and existent-fourth dimension electricity. Int J Energ Res 42(12):3928–3942

-

Lei DM, Gao Fifty, Zheng YL (2018) A novel educational activity-learning-based optimization algorithm for energy-efficient scheduling in hybrid flow shop. IEEE Trans Eng Manage 65(2):330–340

-

Leo Due east, Engell S (2018) Integrated day-ahead energy procurement and product scheduling. AT-Autom 66(eleven):950–963

-

Li JQ, Sang HY, Han YY et al (2018) Efficient multi-objective optimization algorithm for hybrid flow shop scheduling problems with setup free energy consumptions. J Clean Prod 181:584–598

-

Li XY, Lu C, Gao L (2018) An effective multiobjective algorithm for free energy-efficient scheduling in a real-Life welding store. IEEE Trans Ind Inform 14(12):5400–5409

-

Liu GS, Li JJ, Tang YS (2018) Minimizing total idle free energy consumption in the permutation flow shop scheduling problem. Asia Pac J Oper Res 35(half-dozen):1850041

-

Liu Y, Farnsworth Chiliad, Tiwari A (2018) Energy-efficient scheduling of flexible flow shop of composite recycling. Int J Adv Manuf Technol 97(one–4):117–127

-

Lu C, Gao L, Li XY et al (2018) A multi-objective arroyo to welding shop scheduling for makespan, noise disturbance and energy consumption. J Clean Prod 196:773–787

-

Meziane MEA, Taghezout N (2018) Predictive reactive approach for energy-aware scheduling and control of flexible manufacturing processes: application on flexible chore store. Int J Inform Syst Supply Concatenation Manage eleven(4):43–62

-

Wang FC, Deng GL, Jiang T et al (2018) Multi-objective parallel variable neighborhood search for energy consumption scheduling in blocking catamenia shops. IEEE Access 6:68686–68700

-

Wang H, Jiang ZG, Wang Y et al (2018) A two-stage optimization method for energy-saving flexible job-shop scheduling based on free energy dynamic characterization. J Make clean Prod 188:575–588

-

Wu XL, Shen XL, Cui Q (2018) Multi-objective flexible flow shop scheduling trouble considering variable processing fourth dimension due to renewable energy. Sustainability 10(3):841

-

Wu Twoscore, Lord's day YJ (2018) A green scheduling algorithm for flexible job shop with energy-saving measures. J Clean Prod 172:3249–3264

-

Zhang HL, Ge HJ, Pan RL et al (2018) Multi-objective bi-level programming for the energy-aware integration of flexible job shop scheduling and multi-row layout. Algorithms eleven(12):210

-

Zhang 20, Ji ZC, Wang Y (2018) An improved SFLA for flexible job shop scheduling problem considering energy consumption. Mod Phys Lett B 32(34–36):1840112

-

Zhao SN, Grossmann IE, Tang Lx (2018) Integrated scheduling of rolling sector in steel production with consideration of energy consumption under time-of-use electricity prices. Comput Chem Eng 111:55–65

-

Cui WW, Li 50, Lu ZQ (2019) Energy-efficient scheduling for sustainable manufacturing systems with renewable energy resources. NAV Res Log 66(ii):154–173

-

Faria G, Vieira S, Costa Branco PJ (2019) Evolutionary procedure scheduling approach for energy cost minimization in a yeast production manufacturing plant: pattern, simulation, and factory implementation. Energ Syst 10(1):113–139

-

Gong Ten, Toon DP, Luc M et al (2019) Energy- and labor-ware flexible job shop scheduling under dynamic electricity pricing: a many objective optimization investigation. J Make clean Prod 209:1078–1094

-

Gong X, Liu Y, Lohse N et al (2019) energy- and labor-enlightened production scheduling for industrial demand response using adaptive multiobjective memetic algorithm. IEEE Trans Ind Inform 15(two):942–953

-

Hassani ZIM, El Barkany A, El Abbassi I (2019) New model of planning and scheduling for job-shop production system with energy consumption. Manag Prod Eng Rev 10(1):89–97

-

Jiang ED, Wang Fifty (2019) An improved multi-objective evolutionary algorithm based on decomposition for energy-efficient permutation catamenia store scheduling problem with sequence-dependent. Int J Prod Res 57(6):1756–1771

-

Jiang SL, Zhang L (2019) Energy-oriented scheduling for hybrid menstruation store with limited buffers through efficient multi-objective optimization. IEEE Access 7:34477–34487

-

Lei DM, Li K, Wang L (2019) A 2-phase meta-heuristic for multiobjective flexible job shop scheduling problem with total energy consumption threshold. IEEE Trans Cyber 49(3):1097–1109

-

Liu ZC, Guo SS, Wang 50 (2019) Integrated green scheduling optimization of flexible chore shop and crane transportation considering comprehensive free energy consumption. J Make clean Prod 211:765–786

-

Shen K, De Pessemier T, Gong Ten et al (2019) Genetic optimization of energy and failure enlightened continuous product scheduling in pasta manufacturing. Sensors 19(2):297

-

Wu ZJ, Yang KL, Yang JX et al (2019) Energy-efficiency-oriented scheduling in smart manufacturing. J Ambient Intell Hum Comput 10(3):969–978

-

Zhang ZW, Wu LH, Peng T et al (2019) An improved scheduling approach for minimizing total free energy consumption and Makespan in a flexible job shop environment. Sustainability 11(1):179

-

Dai M, Tang DB, Adriana K et al (2019) Multi-objective optimization for free energy-efficient flexible chore shop scheduling trouble with transportation constraints. Robot Comput-Integr Manuf 59:143–157

-

Zheng X, Zhou SC, Xu R et al (2019) Energy-efficient scheduling for multi-objective ii-stage menstruation shop using a hybrid ant colony optimization algorithm. Int J Prod Res. https://doi.org/10.1080/00207543.2019.1642529

-

Fu YP, Tian GD, Fathollahi-Fard AM et al (2019) Stochastic multi-objective modelling and optimization of an free energy-witting distributed permutation flow shop scheduling problem with the total tardiness constraint. J Make clean Prod 226:515–525

-

Schulz S, Neufeld JS, Buscher U (2019) A multi-objective iterated local search algorithm for comprehensive energy-aware hybrid flow shop scheduling. J Make clean Prod 224:421–434

-

Tian G, Ren Y, Feng Y, Zhou MC, Zhang H, Tan J (2019) Modeling and planning for dual-objective selective disassembly using AND/OR graph and detached artificial bee colony. IEEE Trans Ind Inform 15:2456–2468

Acknowledgements

This piece of work was supported by the Faculty Enquiry Grants (FRG) from Macau Academy of Science and Engineering, the National Natural Science Foundation of China (Grant No. 61603169, 61873328), the National Key R&D Program of China (No. 2016YFB0901900), National Natural Science Fund for Distinguished Young Scholars of People's republic of china (Grant No. 61525304), the DongGuan Innovative Inquiry Squad Programme (No. 2018607202007), and the funding from Shandong Provincial Key Laboratory for Novel Distributed Computer Software Technology.

Writer information

Affiliations

Respective author

Additional data

Publisher'due south Annotation

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open up Access This article is distributed under the terms of the Artistic Commons Attribution 4.0 International License (http://creativecommons.org/licenses/past/4.0/), which permits unrestricted employ, distribution, and reproduction in any medium, provided you lot give appropriate credit to the original author(south) and the source, provide a link to the Artistic Eatables license, and indicate if changes were made.

Reprints and Permissions

Almost this article

Cite this article

Gao, M., Huang, Y., Sadollah, A. et al. A review of energy-efficient scheduling in intelligent product systems. Complex Intell. Syst. half-dozen, 237–249 (2020). https://doi.org/10.1007/s40747-019-00122-6

-

Received:

-

Accepted:

-

Published:

-

Outcome Appointment:

-

DOI : https://doi.org/10.1007/s40747-019-00122-6

Keywords

- Production scheduling

- Energy efficiency

- Swarm intelligence

- Evolutionary algorithm

Source: https://link.springer.com/article/10.1007/s40747-019-00122-6

0 Response to "Sustainability in Manufacturing Operations Scheduling a State of the Art Review"

Post a Comment